Metal roof flashing plays a central role in protecting a building from water infiltration. It forms a barrier at vulnerable junctions where roofing materials meet other structural elements, such as chimneys, walls, skylights, and valleys.

Without effective flashing, even the most durable roof coverings can allow moisture to enter, leading to structural deterioration, mould growth, and costly repairs.

Exploring the purpose, types, and installation considerations of flashing helps clarify why it remains an essential component of any well-constructed roof.

Why Flashing Matters

Every roof contains points where materials change direction or meet different surfaces. These intersections naturally create small gaps or irregularities that can allow water to penetrate. Flashing is used to ensure these weak spots remain watertight.

On metal roofs, the smooth surface encourages water to flow quickly, but it can also send water directly toward seams and junctions. Flashing guides this flow away, ensuring moisture drains off the roof efficiently. Properly installed flashing prevents long-term issues such as timber rot, corrosion, insulation damage, and internal dampness. For buildings in areas that experience heavy rainfall or strong winds, well-designed flashing is particularly crucial.

Common Types of Flashing Used on Metal Roofs

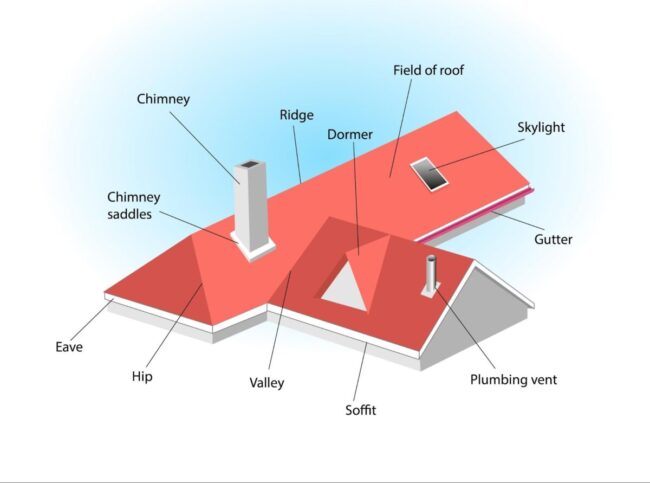

Valley Flashing

Valley flashing sits in the internal angles where two roof slopes meet. These points accumulate water as it runs down the roof, making them prone to leaks if not adequately protected. Robust valley flashing directs water safely down to the gutters.

Sidewall and Headwall Flashing

Where the roof meets an adjoining wall, flashing is required to keep water from slipping behind the cladding or masonry.

- Sidewall flashing runs along the vertical junctions at the side of a roof slope.

- Headwall flashing is placed at the top edge where a roof meets a vertical surface. Both types ensure water does not collect or seep into the building envelope.

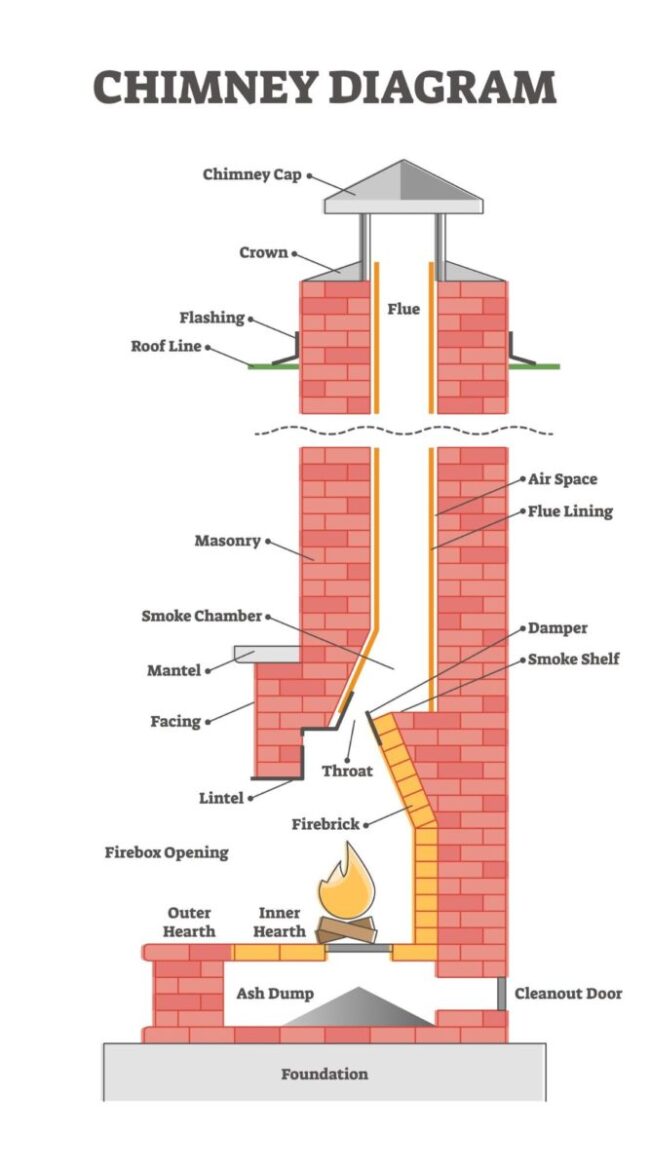

Chimney and Skylight Flashing

Protrusions through the roof require specialised attention. Chimneys, for instance, need a combination of step flashing and counter-flashing to ensure water is directed away from the masonry.

For wider chimneys or penetrations located at the bottom of a steep slope, a structural element known as a “cricket” (or saddle) is often required behind the stack. A cricket is a small, peaked ridge built to divert water around the obstruction rather than allowing it to pool against the back face. Without this diversion, the sheer volume and velocity of water rushing down a metal roof can overwhelm standard flashing seals, leading to inevitable leaks over time.

Skylights are usually supplied with integrated flashing kits designed to match the pitch and material of the roof.

Ridge and Hip Flashing

Ridges and hips form natural high points on the roof. Flashing placed along these lines protects seams while allowing for ventilation where required. On metal roof systems, ridge flashing is often pre-formed to fit the profile of the panels.

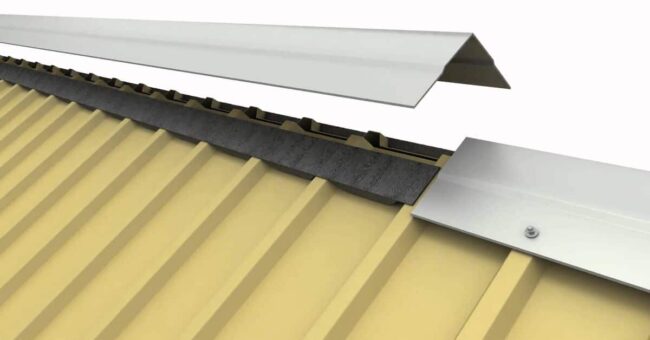

Drip Edge Flashing

Installed along the edges of the roof, drip edge flashing prevents water from running underneath the roofing material or into the fascia. It promotes controlled drainage into the guttering system and protects the timber structure beneath.

Materials and Durability Considerations

Metal roof flashing is typically made from galvanised steel, aluminium, or copper. Each material provides different performance characteristics:

- Galvanised steel offers strength and durability at an affordable price.

- Aluminium is lightweight and resistant to corrosion, making it suitable for coastal areas.

- Copper provides exceptional longevity and aesthetic appeal, though it is more costly.

Matching the flashing material with the roofing system helps prevent galvanic corrosion. Using incompatible metals can lead to accelerated deterioration, so choosing suitable materials is an essential part of planning.

Beyond the raw material, the finish of the flashing is equally important for longevity and aesthetics. Most modern metal flashing is coated with high-performance PVDF resin-based finishes (such as Kynar 500). These coatings provide superior resistance to chalking and fading, ensuring the flashing maintains its colour match with the roof panels for decades. Choosing a factory-applied finish prevents the flashing from becoming an aesthetic eyesore or a rust point, effectively acting as the first line of defence against UV radiation and acidic environmental pollutants.

Installation Principles

Effective flashing installation depends on correct placement and secure fixing. Overlaps should be generous enough to accommodate water flow and resist wind uplift. Sealants may be used, but they should not replace mechanical fixes; flashing must be able to withstand the elements independently of adhesives.

A critical factor often overlooked during installation is the thermal expansion and contraction of metal. Unlike asphalt shingles, metal panels expand significantly in heat and contract in cold. If flashing is rigidly fixed without allowing for this movement, it can warp, buckle, or tear at the fastener points, a phenomenon known as “oil canning.” Professional installers often use sliding clips or slotted holes in the flashing details to accommodate this shift, ensuring the barrier remains flat and intact through changing seasons.

Pitch also plays a role. Roofs with low slopes require more robust flashing solutions because water drains more slowly. High-pitched roofs depend on precise shaping to ensure water flows as intended.

Maintenance and Inspection

Although flashing is durable, regular inspection helps prevent issues from developing. Over time, fixings may loosen, sealants may degrade, and metal can corrode if exposed to standing water. Early signs of wear include rust spots, gaps at joints, lifting edges, or damp patches in the interior of the building. Addressing these concerns quickly preserves the overall life of both the flashing and the roof structure.

The Role of Flashing in Modern Roofing

As roofing systems evolve, flashing remains indispensable. Advances in metal roof design have improved durability and energy performance, yet the fundamental need to control water remains unchanged. Modern systems often integrate flashing components more seamlessly, but the underlying principles stay the same: directing water away from vulnerable areas and ensuring the integrity of the building.

For anyone considering a roofing upgrade or new installation, understanding metal roof flashing offers valuable insight into how roofs perform and what makes them last.